Manufacturing Project Now!

NUTRASELLER Gummy Vitamin Manufacturing Process

Gummy Vitamin Manufacturing Overview

Gummy Formulation & Flavoring

Gummy Ingredient Sourcing

Quality Control

Gummy Mixing and Heating

Gummy Molding and Shaping

Gummy Cooling and Setting

Gummy Drying

Coating and Polishing

Quality Assurance

Gummy Packaging

Labeling and Branding

Understanding the Equipment, Tools & Methods to Manufacture Gummies at Scale

Critical equipment and machinery are essential to produce gummy vitamins at a large scale.

- Molds: Molds are one of the fundamental tools in creating gummy vitamins. These molds determine the shape and size of the final product.

- Gummy Vitamin Production Equipment: This equipment consists of a mixing unit, a cooking unit, a depositing unit, cooling unit and a coating unit.

- Gummy Counter & Packaging Line: A gummy counter is crucial in accurately measuring and packaging gummy vitamins. It counts the gummies as it fills the package, ensuring the correct quantity and sealing and tamper-proofing the product.

Molds

Molds play a crucial role in creating gummy vitamins, as they determine the shape and appearance of these chewy and delightful supplements.

Using different mold types, you can produce appealing shapes that cater to diverse consumer preferences.

Two Types of Molds Used

- Stock Molds: These pre-existing molds produce various gummies in the same shape concurrently.

- Customized Molds: Custom molds are designed to align with a brand’s unique requirements, featuring bespoke shapes, intricate designs, or embedded logos.

Mixing Unit

The first step in the cooking phase is meticulously mixing ingredients. Gummy vitamins typically contain various components, including vitamins, minerals, flavorings, colorings, and a gelling agent. The gelling agent is responsible for giving gummy vitamins their chewy texture. The ingredient mixing process requires careful measurement and precise calculations to ensure the correct ratio of each component in the gummy mixture.

One popular vegetarian gelling agent is agar, a seaweed-derived ingredient. Agar not only provides the desired texture but also ensures a low rate of water solubility, allowing the gummy to hold its shape without becoming too sticky or watery. When creating custom gummy formulations, we often incorporate specific properties of the gelling agent to meet consumers’ nutritional needs and preferences. For example, a brand might choose a plant-based substance like pectin as an alternative additive to cater to a vegan market segment.

Heating Unit

Once the ingredients are perfectly mixed, the gummy mixture undergoes a heating process. The heating temperature and duration are critical factors in achieving the ideal texture and consistency of the gummy vitamins. The mixture is heated in an industrial cooker for gummy vitamins, facilitating efficient and controlled heating. The temperature adjustment is carefully monitored during heating to prevent the ingredients from degrading or losing their nutritional potency. The heating stage allows the ingredients to meld together, resulting in a homogenous mixture that will later solidify into gummy form.

Mixture Depositing Unit

In this step, the gummy mixture is carefully transferred to specialized molds designed to create the distinctive shape and form of gummy vitamins. The gummy mixture is deposited into the molds using a dosing system to ensure accurate and precise results. This system allows precise control over the amount of mixture dispensed, ensuring that each gummy vitamin is consistent in size and dosing.

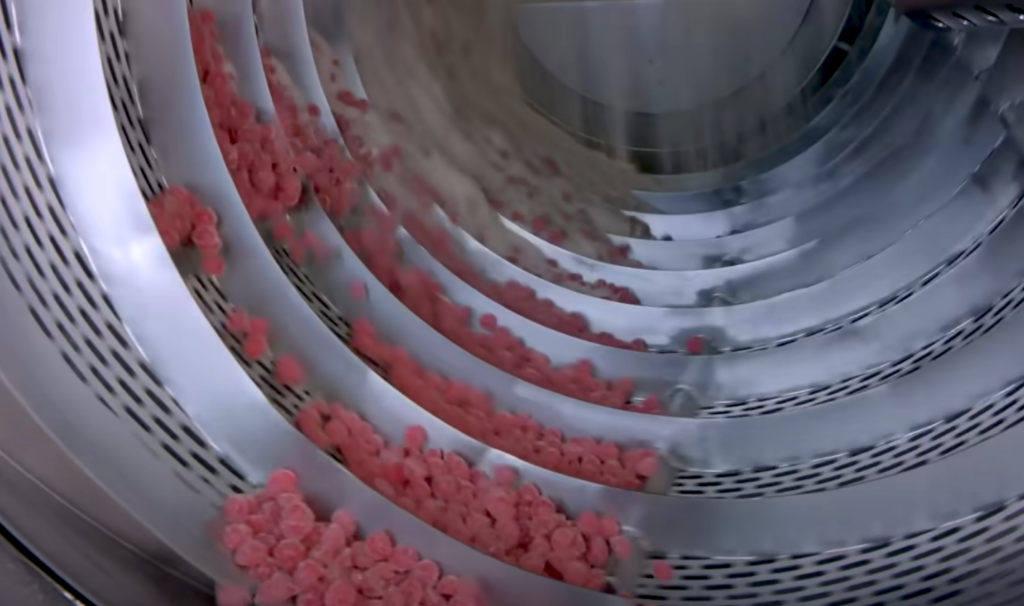

Cooling Unit

The molds with the solidified mixture are deposited & moved to a cooling chamber, where controlled temperature conditions help accelerate solidification. During the cooling phase, the gummy vitamins transform from a liquid-like state to a chewy, solid texture. Proper temperature control is essential during this phase to ensure that the gummy vitamins maintain their desired shape without deformities or imperfections. Monitoring and maintaining the appropriate cooling conditions are critical.

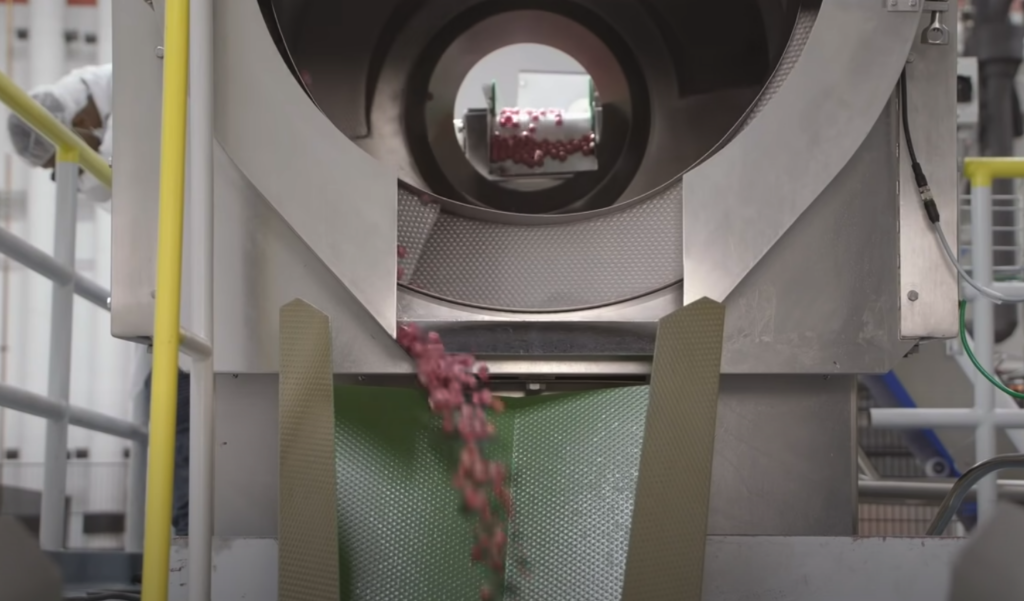

Coating Unit

The Coating Process

1. Preparation: Once the gummy vitamins have been molded into their desired shape, they are ready for the coating process. Before coating, the gummies undergo a careful inspection to ensure their uniformity and integrity.

2. Coating Solution: A coating solution is prepared, consisting of various ingredients such as sugars, oils, and natural or artificial colorings. This solution provides a better appearance and helps protect the delicate gummy from external factors.

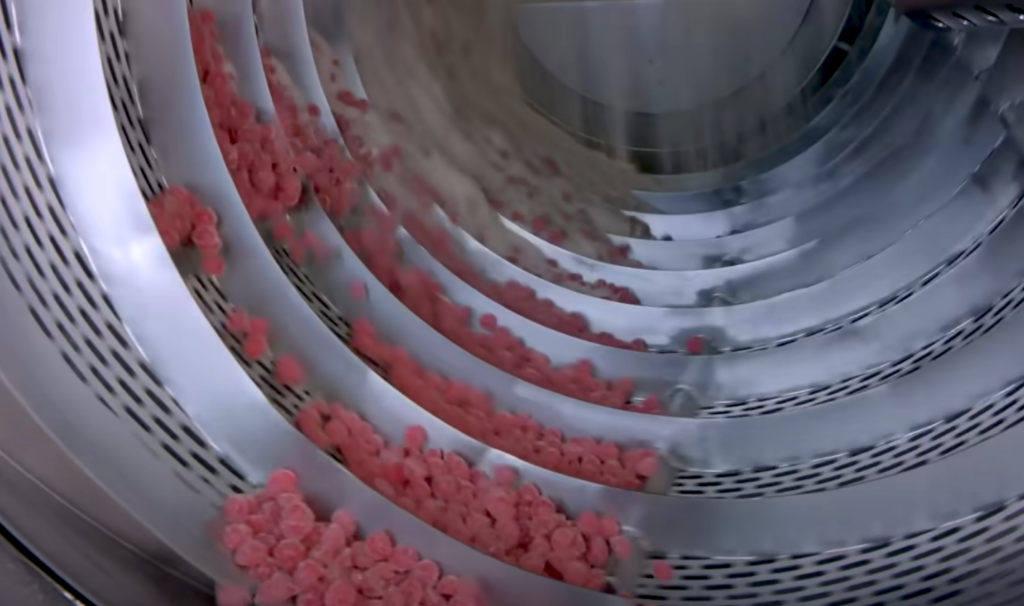

3. Coating Application: The gummies are carefully placed into a coating machine that evenly applies the coating solution. This machine is designed to rotate the gummies while applying the coating, ensuring a consistent and thorough covering.

4. Coating Drying Process: The gummies are transferred to a drying chamber after applying the coating. Here, controlled temperature and humidity levels facilitate drying, allowing the coating to set and harden.

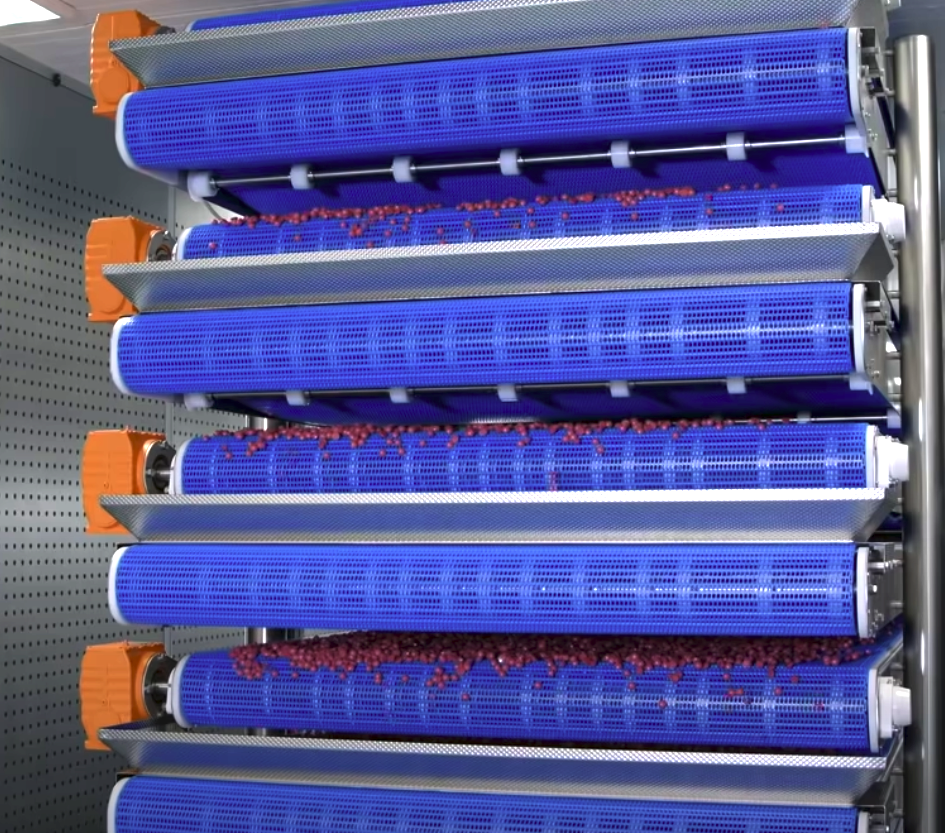

Gummy Counter

Functionality: The gummy counter is designed to accurately count the number of gummies in each package. This ensures that consumers receive the exact quantity of gummies stated on the packaging.

Technology: Modern gummy counters use advanced sensors and optical systems to detect and count each piece as it passes through the conveyor. These systems can adjust to different sizes and shapes of gummies, maintaining accuracy and efficiency.

Integration: The counting machine is often integrated with the production line to streamline the process from manufacturing to packaging, reducing manual handling and the potential for error.

Packaging Line

Filling and Sealing: Gummies are automatically dispensed into containers or pouches after counting. These packages are then sealed to prevent contamination, preserve freshness, and ensure product safety during transportation and storage.

Tamper-Evident Features: Packaging lines include mechanisms to apply tamper-evident seals, ensuring the product hasn’t been opened or tampered with before purchase. This is crucial for consumer trust and regulatory compliance.

Labeling and Coding: The packaging line also includes equipment for labeling, where product information, nutritional facts, and branding are applied. As well as batch codes, expiration dates, and tracking information are printed to facilitate quality control and recall processes.

Minimums & Average Turnaround Time For Gummy Vitamin Manufacturing

MOQ

Turnaround

Private label in-stock

100,000 gummies

2-4 weeks

Custom formula

1,000,000 gummies

4 months

Our Stock Private Label Gummy Vitamins

Next Steps - PRIVATE LABELING Your Gummy Vitamin Finished Product

Discussion

Pricing & Strategy

Gummy Vitamin Manufacturing

Label Design & Compliance

Dedicated Support

Shipping Your Finished Product

Strategizing Your Restock

Gummy Vitamins Are Exploding in Popularity In The Past Few Years

Why Are Gummy Vitamins So Popular?

- Taste and Texture: One of the primary reasons behind the widespread popularity of gummy vitamins is their enjoyable taste and chewy texture. Unlike traditional pill or capsule supplements, which often come with the side effect of an unpleasant taste and the experience of swallowing a pill, gummy vitamins come in various delicious flavors, making them more like a treat than a chore to consume. This makes them particularly appealing to individuals who struggle with swallowing pills.

- Convenience and Ease of Consumption: Gummy vitamins offer ultimate convenience and ease of consumption. They eliminate the need for water and can be taken anywhere without hassle. This makes them perfect for individuals with busy lifestyles who may only sometimes have access to water or may find it inconvenient to swallow a pill.

- Fun and Engaging: For adults and children alike, gummy vitamins bring fun and playfulness to the daily supplement routine. The vibrant colors and fruity flavors make them more enjoyable, turning what could be a mundane task into a delightful experience.

- Increased Consumption from Consumers: The pleasant taste and enjoyable experience of consuming gummy vitamins can lead to increased consumption, which results in more consistent & frequent repeat buyers. Individuals who have previously struggled to take their supplements consistently may find incorporating gummy vitamins into their daily routine much easier and more enjoyable.

Gummy Vitamin Popularity by the Numbers

Gummy vitamins have experienced a significant surge in popularity in recent years, with more and more individuals turning to these chewy and flavorful supplements to meet their nutritional needs.

Let’s look at some eye-opening statistics and market trends highlighting the increasing demand for gummy vitamins.

- Market Growth: A study from Grand View Research highlights that the gummy market size was valued at $23.93 billion in 2023, with a projected growth rate of 11.8% from 2024 to 2030. This growth is fueled by increasing consumer demand for functional and fortified gummy products, available in various flavors, offering health benefits along with taste. Mordor Intelligence further details the segmentation and growth factors of the gummy vitamin market, noting a compound annual growth rate (CAGR) of 8.52% during the forecast period from 2024 to 2029. The market is segmented by category (such as prenatal, kids, and adults), type (single vitamins and multivitamins), and distribution channel (including supermarkets/hypermarkets, pharmacies, and online retail stores), indicating a broad and diverse consumer base and market presence.

- Consumer Base: Gummy vitamins have attracted a broad and enthusiastic consumer base. Their ease of consumption, delicious flavors, and enjoyable texture make them a popular choice across various age groups, including children, adults, and seniors.

- Convenience Factor: The convenience factor associated with gummy vitamins has contributed significantly to their rising popularity. Unlike traditional pills or tablets, gummy vitamins are easy to chew and swallow. They eliminate the need for water and make them suitable for individuals who have difficulty swallowing pills.

- Taste Appeal: The delicious taste of gummy vitamins is vital in their growing popularity. Gummy vitamins come in various flavors, including fruity options like strawberry, orange, and cherry. They appeal to those who may need more than traditional supplement pill forms.

- Alternative Option: Gummy vitamins have also emerged as an alternative option for individuals who are averse to taking pills. The chewable nature of gummies allows for a more enjoyable and hassle-free supplementation experience.

The increasing demand for gummy vitamins demonstrates a shifting trend in how consumers approach their nutritional needs.

As more people discover the benefits and convenience of these delightful chewable supplements, the popularity of gummy vitamins is expected to continue its upward trajectory.

“The global gummy vitamin market is projected to reach $30 billion by 2025. For comparison, that is the same market size as luxury watches for just gummy vitamins alone.

This indicates the significant growth and consumer acceptance of these chewable supplements, which is a relatively new trend that emerged in the nutraceutical industry in the last five years.

Compared to ultra-competitive luxury watch brands and most other consumer packaged goods today, there is more opportunity with fewer costs for a relative newcomer brand to start a successful gummy vitamin brand from nothing.”

– William Cartwright | CEO & Founder of NutraSeller